In the world of manufacturing and engineering, precision is key, especially when it comes to working with flanges in piping systems and sheet metal fabrication. Flanges are critical components that connect pipes, valves, and other equipment, ensuring a secure and leak-proof assembly. With the advent of technology, the availability of free online flange tools has revolutionized how engineers and fabricators approach their work. This blog explores the benefits of using free online flange tools and the importance of flange tools for sheet metal fabrication.

Understanding Flanges and Their Applications

Flanges are mechanical components that provide a means of connecting two parts, typically pipes or fittings. They come in various shapes and sizes, including weld neck, slip-on, blind, and threaded flanges. The choice of flange type depends on the specific application, pressure requirements, and material compatibility. Flanges are widely used in industries such as oil and gas, water treatment, HVAC, and manufacturing.

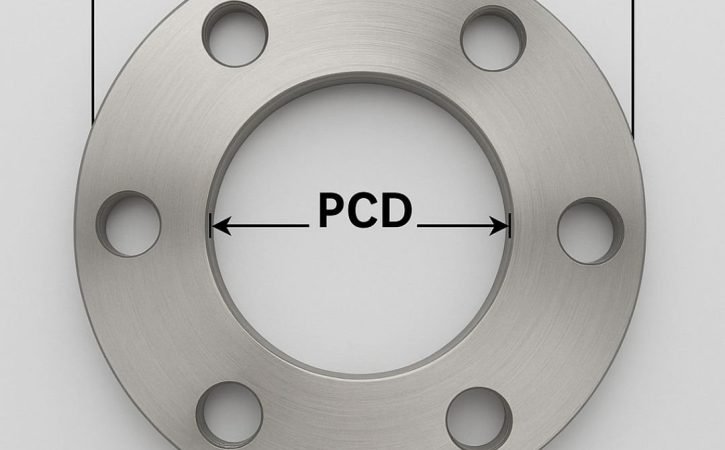

The Importance of Accurate Flange Measurements

Accurate measurements are crucial when working with flanges. A poorly fitted flange can lead to leaks, pressure loss, and even catastrophic failures in piping systems. Therefore, having the right tools to measure and design flanges is essential for ensuring the integrity and safety of any assembly. This is where flange tools come into play.

The Benefits of Free Online Flange Tools

1. Accessibility and Convenience

One of the most significant advantages of free online flange tool for sheet metal is their accessibility. Engineers and fabricators can access these tools from anywhere with an internet connection, eliminating the need for expensive software or physical tools. This convenience allows users to perform calculations and measurements on the go, making it easier to integrate flange design into their workflow.

2. Cost-Effective Solution

For small businesses and independent contractors, investing in expensive flange design software can be a significant financial burden. Free online flange tools provide a cost-effective solution, allowing users to access essential features without the associated costs. This democratization of technology enables more professionals to engage in precise flange design and measurement.

3. User-Friendly Interfaces

Many free online flange tools are designed with user-friendly interfaces, making them accessible to individuals with varying levels of expertise. These tools often come with intuitive layouts, step-by-step instructions, and helpful tutorials, allowing users to quickly learn how to use them effectively. This ease of use can significantly reduce the learning curve associated with traditional flange measurement methods.

4. Instant Calculations and Results

Free online flange tool can perform complex calculations in seconds, providing users with instant results. This speed is particularly beneficial in fast-paced environments where time is of the essence. Users can quickly input their specifications and receive accurate measurements, allowing them to make informed decisions without delay.

5. Integration with Other Tools

Many online flange tools can integrate with other design and engineering software, enhancing their functionality. This interoperability allows users to streamline their workflow, making it easier to incorporate flange design into larger projects. Whether you are working on a CAD program or a project management tool, having a flange tool that integrates seamlessly can save time and improve efficiency.

Flange Tools for Sheet Metal Fabrication

In addition to online flange tools, specialized flange tools for sheet metal fabrication are essential for creating and shaping flanges accurately. These tools are designed to work with sheet metal, allowing fabricators to create flanges that provide strength and stability to metal components.

Key Features of Flange Tools for Sheet Metal

-

Flanging Capability: Flange tools for sheet metal are designed to create flanges by bending the edges of the metal. This process is crucial for providing structural integrity to components used in various applications, including HVAC systems and ductwork.

-

Adjustable Settings: Many flange tools come with adjustable settings, allowing users to customize the flange dimensions according to their specific project requirements. This flexibility is essential for accommodating different designs and specifications.

-

Durability and Strength: These tools are typically made from high-strength materials to withstand the forces involved in bending and shaping metal. They are designed for heavy-duty use in industrial settings, ensuring reliability and longevity.

-

Ease of Operation: Flange tools for sheet metal are often designed for ease of use, allowing operators to create flanges quickly and efficiently. Many tools feature ergonomic designs that reduce operator fatigue during extended use.

The Importance of Flange Tools in Sheet Metal Fabrication

Flange tools for sheet metal fabrication are vital for several reasons:

-

Precision Fabrication: Accurate flanging is essential for ensuring that sheet metal components fit together correctly. This precision is crucial in applications such as HVAC systems, where proper sealing is necessary to maintain efficiency.

-

Versatility: Flange tools can be used for various applications, including ductwork, enclosures, and custom metal fabrications. This versatility makes them valuable in many industries, from construction to manufacturing.

-

Cost-Effectiveness: By enabling efficient fabrication of flanges, these tools can help reduce material waste and labor costs. Accurate flanging minimizes the need for rework and adjustments, saving time and resources.

-

Enhanced Structural Integrity: Properly flanged sheet metal components provide added strength and stability to assemblies. This is particularly important in applications where structural integrity is critical, such as in building construction and industrial equipment.

Conclusion

The availability of free online flange tools has transformed the way engineers and fabricators approach flange design and measurement. These tools offer accessibility, cost-effectiveness, and user-friendly interfaces, making them invaluable resources in the industry. Additionally, specialized flange tools for sheet metal fabrication play a crucial role in creating accurate and reliable flanges, ensuring the integrity of various applications.

By leveraging both free online flange tools and dedicated flange tools for sheet metal, professionals can enhance their precision, efficiency, and overall quality of work. As technology continues to evolve, embracing these tools will be essential for staying competitive in the ever-changing landscape of manufacturing and engineering. Whether you are a seasoned professional or just starting in the field, investing time in learning and utilizing these tools will undoubtedly pay off in the long run.

Category

Have any Query? Feel free to drop a mail to us.