In today’s rapidly evolving industrial landscape, selecting the right type of fittings is essential for ensuring long-term performance, durability, and safety. Whether it is for chemical plants, marine applications, oil & gas projects, or large-scale manufacturing units, engineers depend heavily on high-quality fittings to maintain seamless and leak-proof operations. Among the most widely used options, Aluminium Fittings manufacturers and Carbon Steel Forged Fittings suppliers play a major role in meeting the diverse needs of global industries. Understanding the differences and advantages of each helps buyers make informed decisions based on project specifications, environmental conditions, and budget requirements.

Why Aluminium Fittings Are Gaining Popularity

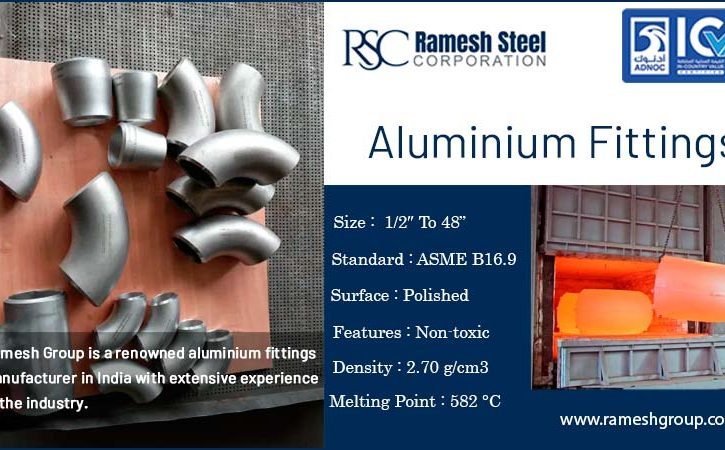

Aluminium fittings are becoming increasingly popular because of their light weight, corrosion resistance, and versatility. Leading Aluminium Fittings manufacturers provide a wide variety of components such as elbows, tees, couplings, unions, reducers, hose connectors, and threaded fittings that cater to both industrial and commercial use.

One of the biggest advantages of aluminium is its excellent strength-to-weight ratio. In industries where weight reduction is critical, such as aeronautics, automotive systems, and marine equipment, aluminium fittings offer exceptional advantages. They are easy to install, transport, and maintain, which helps reduce overall operational costs.

Additionally, aluminium has natural corrosion-resistant properties due to the formation of a protective oxide layer. This makes aluminium fittings ideal for applications exposed to moisture, chemicals, and outdoor environments. Many Aluminium Fittings manufacturers enhance this durability further by offering anodized or powder-coated finishes, ensuring even greater resistance to wear, oxidation, and surface damage.

Where Are Aluminium Fittings Used?

Some of the most common industries that rely on aluminium fittings include:

-

Aerospace & Aviation – Lightweight yet strong connectors that support fuel, ventilation, and hydraulic systems.

-

Automotive & Transport – Used in air-conditioning lines, fuel systems, brake tubing, and engine components.

-

Water Treatment & Plumbing – Corrosion-resistant fittings ideal for non-aggressive fluids.

-

Marine Manufacturing – Perfect for vessels, docks, and marine structures exposed to saltwater environments.

-

General Engineering – Popular in small machines, compressors, and custom fabrication work.

Because of their versatility and long service life, aluminium fittings have become a preferred choice for projects that demand high performance without adding unnecessary weight.

The Strength & Reliability of Carbon Steel Forged Fittings

While aluminium fittings excel in lightweight and corrosion-resistant applications, Carbon Steel Forged Fittings dominate industries where extreme strength, high pressure, and resistance to impact are non-negotiable. These fittings are manufactured through a forging process that compresses steel under high pressure, resulting in superior mechanical properties.

Carbon steel is known for its excellent tensile strength, making it suitable for high-pressure piping systems found in oil refineries, power plants, petrochemical industries, and heavy engineering sectors. The forging process refines the grain structure of steel, significantly increasing durability and reducing the chances of leaks or failures under stress.

Types of Carbon Steel Forged Fittings

Commonly produced forged fittings include:

-

Socket Weld Fittings – Couplings, tees, caps, and reducers for high-pressure pipelines.

-

Threaded Fittings – Elbows, plugs, bushings, unions, and street elbows designed for easy installation.

-

High-Pressure Specials – Components ideal for critical applications in oil & gas and hydraulic systems.

These fittings are widely used in high-temperature and high-pressure environments where aluminium cannot perform effectively. Their rugged structure and excellent resistance to wear make them essential for industrial systems that require maximum reliability.

Applications of Carbon Steel Forged Fittings

The industries that most commonly rely on carbon steel fittings include:

-

Oil & Gas Industry – High-pressure pipelines, drilling rigs, and refinery systems.

-

Power Generation – Steam lines, boilers, turbines, and heat exchangers.

-

Petrochemicals & Fertilizers – Chemical processing lines that handle harsh fluids.

-

Heavy Machinery Manufacturing – Hydraulic equipment and industrial pumps.

-

Construction & Infrastructure – Structural supports, pipelines, and welding assemblies.

Their ability to withstand tough working conditions, temperature fluctuations, and mechanical stress makes carbon steel forged fittings the backbone of critical industrial operations.

Aluminium vs Carbon Steel: Which Should You Choose?

Choosing between aluminium fittings and Carbon Steel Forged Fittings depends on the specific needs of your project. When weight savings, corrosion resistance, and easy handling matter, aluminium is the ideal choice. However, when strength, pressure resistance, and long-term toughness are required, carbon steel forged fittings clearly outperform.

Final Thoughts

Both Aluminium Fittings manufacturers and Carbon Steel Forged Fittings suppliers play an important role in today’s industrial supply chain. By understanding the benefits, applications, and performance of each material, businesses can invest in the right type of fittings that ensure safety, efficiency, and long-term value. Whether your industry demands lightweight aluminium solutions or rugged forged carbon steel components, choosing high-quality fittings always leads to better operational outcomes and improved project reliability.