Introduction:

In the world of metallurgy, where strength, corrosion resistance, and durability are paramount, super duplex stainless steel has emerged as a true champion. Among its various forms, super duplex round bar and forged fittings have gained significant popularity due to their exceptional properties and wide-ranging applications. This blog aims to shed light on the remarkable characteristics of super duplex round bars and forged fittings, exploring their significance in diverse industries.

Understanding Super Duplex Stainless Steel:

Super duplex stainless steel is a robust alloy that combines the desirable attributes of both austenitic and ferritic stainless steels. It is composed of a balanced mixture of chromium, molybdenum, and nitrogen, with higher percentages of these elements compared to standard duplex stainless steel. This unique composition imparts exceptional strength, resistance to corrosion, and enhanced toughness to the material.

Super Duplex Round Bars:

Super duplex round bars are cylindrical bars made from super duplex stainless steel. These bars are known for their high tensile strength, making them suitable for applications requiring structural integrity under extreme conditions. Some notable features of super duplex round bars include:

- Corrosion Resistance: Super duplex round bars exhibit superior resistance to various corrosive environments, including chloride-induced stress corrosion cracking and pitting corrosion. This makes them ideal for applications in offshore and marine industries, chemical processing plants, and oil and gas refineries.

- High Yield Strength: Super duplex round bars possess a higher yield strength compared to conventional stainless steels. This attribute enables them to withstand heavy loads, making them suitable for applications in the construction of bridges, buildings, and other infrastructure projects.

- Temperature and Pressure Resistance: These round bars demonstrate excellent resistance to high temperatures and pressures, making them an ideal choice for applications in the petrochemical, power generation, and desalination industries.

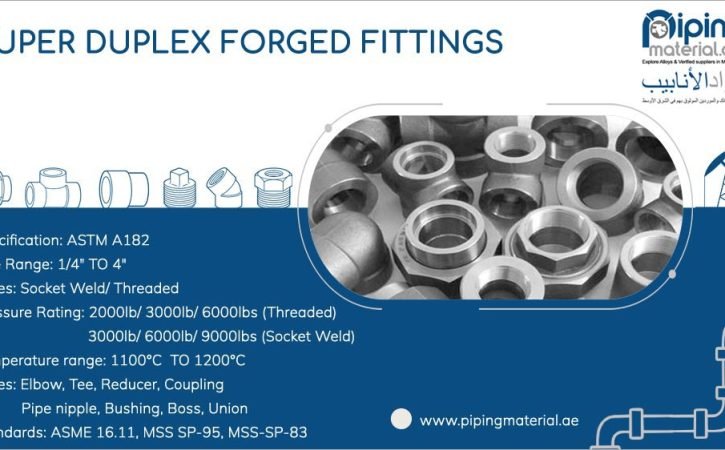

- Super Duplex Forged Fittings:

Forged fittings are components manufactured by forging solid metal blocks into desired shapes. Super duplex forged fittings offer exceptional strength and reliability. They are extensively used in critical applications where leakage or failure can have severe consequences. Key features of super duplex forged fittings include:

- Leak-Free Performance: Super duplex forged fittings ensure leak-free connections due to their excellent mechanical properties and precise manufacturing. They are commonly used in pipelines, oil and gas installations, and chemical processing plants.

- Easy Installation: These fittings are designed for easy installation and maintenance. They are available in various shapes and sizes, such as elbows, tees, couplings, and unions, to accommodate diverse piping requirements.

- Resistance to Corrosion and Erosion: Super duplex forged fittings exhibit outstanding resistance to corrosion, erosion, and abrasive media, making them suitable for applications involving corrosive fluids and high-velocity flow conditions.

- Applications:

Super duplex round bars and forged fittings find extensive application across multiple industries, including:

- Oil and Gas: These components are widely used in offshore platforms, subsea installations, and pipelines for their resistance to corrosion and high strength.

- Chemical and Petrochemical: Super duplex round bars and forged fittings are employed in chemical processing plants, reactors, and storage tanks, where resistance to aggressive chemicals is crucial.

- Desalination: Due to their excellent corrosion resistance, super duplex components are used in desalination plants for the production of fresh water from seawater.

- Construction and Infrastructure: The high strength and durability of super duplex round bars make them suitable for construction projects requiring structural integrity and longevity.

Conclusion:

Their unique properties make them indispensable in critical applications where safety, reliability, and performance are paramount. With ongoing advancements in material science and engineering, super duplex stainless steel continues to evolve, providing innovative solutions for the challenges faced by different sectors

- SHARES