Introduction:

In the world of industrial applications, materials with exceptional properties play a vital role in ensuring efficiency, safety, and reliability. Among these materials, nickel alloys have emerged as a cornerstone in various critical industries. Nickel alloy flanges and pipe fittings are prime examples of how this versatile metal can withstand demanding environments while providing unparalleled performance. In this blog, we delve into the significance, properties, and applications of nickel alloy flanges and pipe fittings, shedding light on their indispensable contributions to modern engineering.

-

Understanding Nickel Alloys:

Nickel alloys are a class of metallic materials predominantly composed of nickel along with various other elements like chromium, molybdenum, iron, copper, and more. The unique combination of these elements imparts exceptional characteristics to the alloys, making them ideal for a wide range of applications, especially in corrosive and high-temperature environments.

-

The Allure of Nickel Alloy Flanges:

2.1 Corrosion Resistance: One of the primary reasons for choosing nickel alloy flanges is their remarkable resistance to corrosion. Whether exposed to harsh chemicals, acids, or saline environments, nickel alloy flanges exhibit outstanding resilience, making them suitable for offshore oil platforms, chemical processing plants, and marine applications.

2.2 High-Temperature Stability: Nickel alloys inherently possess excellent thermal stability and creep resistance, allowing nickel alloy flanges to maintain their structural integrity even in extreme temperatures. This quality finds application in aerospace, gas turbines, and high-temperature industrial processes.

2.3 Superior Strength: Nickel alloy flanges boast high tensile strength and toughness, which makes them suitable for withstanding high pressure and mechanical stresses. These properties are particularly beneficial in oil and gas pipelines and high-pressure processing equipment.

-

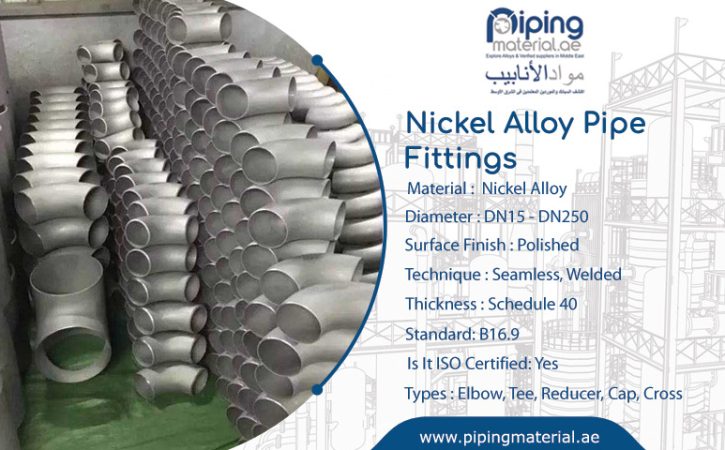

The Versatility of Nickel Alloy Pipe Fittings:

3.1 Seamless Integration: Nickel alloy pipe fittings are designed to seamlessly join sections of pipes, creating a continuous and leak-proof flow path. Their compatibility with various pipe dimensions and configurations ensures efficient fluid transfer in diverse industries.

3.2 Enhanced Weldability: Nickel alloy pipe fittings have excellent weldability, allowing for easy and reliable connections during installation or maintenance. This feature contributes to their popularity in critical systems such as nuclear power plants and chemical processing units.

3.3 Adaptability to Extreme Conditions: With exceptional resistance to both corrosion and oxidation, nickel alloy pipe fittings thrive in extreme environments where conventional materials would falter. They serve as vital components in chemical processing, desalination plants, and power generation facilities.

-

Applications of Nickel Alloy Flanges and Pipe Fittings:

4.1 Oil and Gas Industry: Nickel alloy flanges and pipe fittings find extensive use in the oil and gas sector, particularly in offshore platforms, subsea pipelines, and refining processes. Their resistance to corrosion and high-strength properties ensure reliable and long-lasting performance.

4.2 Chemical Processing: In chemical plants, where corrosive substances are handled, nickel alloy flanges and pipe fittings provide unmatched durability, ensuring the integrity of the systems and preventing leaks or failures that could be catastrophic.

4.3 Aerospace and Defense: Nickel alloy flanges and pipe fittings are crucial in aerospace applications, including aircraft engines and propulsion systems. The ability to withstand high temperatures and harsh conditions makes these materials indispensable for the aerospace and defense industries.

4.4 Power Generation: Power plants, especially those using fossil fuels or nuclear reactors, benefit from the use of nickel alloy flanges and pipe fittings. Their resistance to oxidation and high-temperature stability ensure the efficiency and safety of power generation processes.

Conclusion:

In conclusion, nickel alloy flanges and pipe fittings are truly marvels of modern engineering, offering a unique combination of corrosion resistance, high-temperature stability, and superior strength. Their versatility allows them to thrive in various industries, playing a pivotal role in critical applications where safety, reliability, and efficiency are paramount. As technology continues to advance, we can expect nickel alloys to remain at the forefront of innovation, driving progress across a wide range of industries and applications.

- SHARES