Introduction:

In the world of construction, manufacturing, and various industries, the demand for lightweight, durable, and versatile materials is ever-present. Aluminum, with its remarkable properties, has emerged as a popular choice for a wide range of applications. Aluminum sheets and aluminum tubes, in particular, have gained immense popularity due to their exceptional qualities and adaptability. In this blog, we will explore the versatility and practicality of aluminum sheets and aluminum tubes and delve into their various uses across industries.

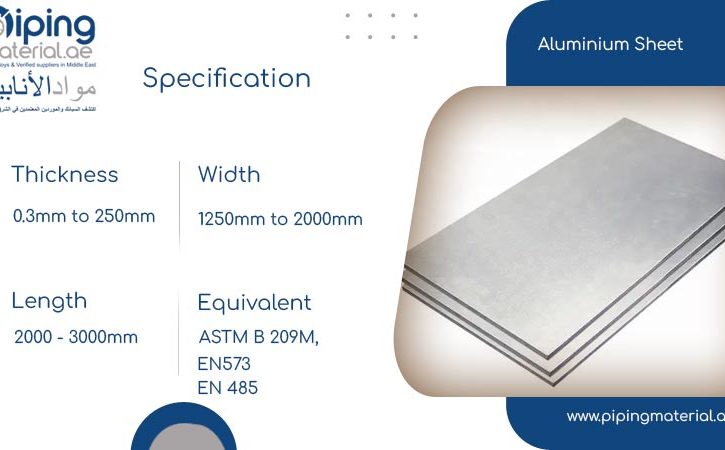

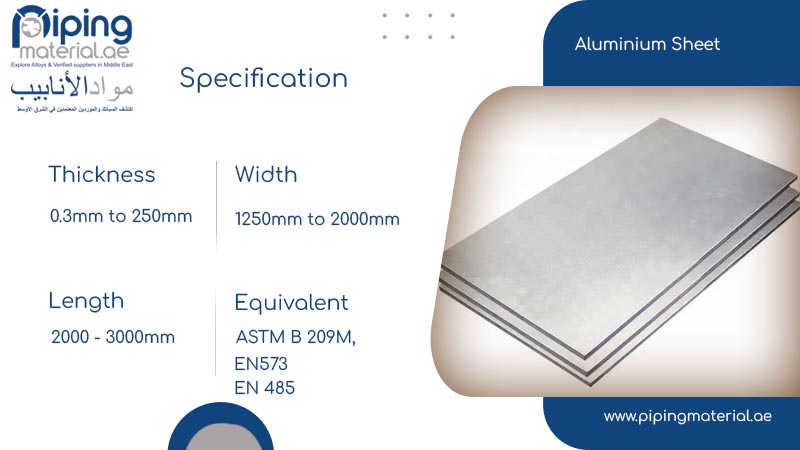

Aluminum Sheets: A Solid Foundation for Innovation

Aluminum sheets are thin, flat pieces of aluminum that come in various sizes and thicknesses. They are produced through a process known as rolling, which involves passing heated aluminum blocks between heavy rollers to reduce the thickness and create the desired sheet. The resulting Aluminium tube possess several remarkable properties that make them an ideal material for numerous applications.

Lightweight and Strong: One of the key advantages of aluminum sheets is their impressive strength-to-weight ratio. Aluminum is about one-third the weight of steel, making it an excellent choice for applications where weight reduction is critical without compromising strength. This characteristic makes aluminum sheets highly desirable for aerospace, automotive, and marine industries.

Corrosion Resistance: Aluminum naturally forms a protective oxide layer when exposed to air, providing exceptional corrosion resistance. This unique feature ensures that aluminum sheets remain durable and long-lasting even in harsh environments. Consequently, they are widely used in construction, outdoor signage, and architectural applications.

Aluminum sheets are frequently used in applications where thermal management or electrical conductivity is required, such as heat sinks, electronic enclosures, and power transmission lines.

Formability and Versatility: Aluminum sheets can be easily formed, bent, cut, or welded, allowing for a wide range of design possibilities. From automotive body panels to kitchen appliances, aluminum sheets find their way into various industries due to their exceptional formability and versatility.

Aluminum Tubes: Strength in Seamless Structures

Aluminum tubes, similar to aluminum sheets, possess several remarkable properties that make them invaluable across numerous industries. They are typically hollow cylindrical structures with a variety of diameters and wall thicknesses. Let’s explore the key features of aluminum tubes.

Lightweight Construction: Aluminum tubes offer an excellent balance between strength and weight, making them a preferred choice for lightweight structural applications. Industries such as aerospace, automotive, and bicycle manufacturing benefit greatly from the weight reduction achieved by incorporating aluminum tubes.

Ductility and Malleability: Aluminum tubes can be easily formed and bent into various shapes without losing their structural integrity. This malleability allows for complex designs and seamless structures, enhancing their versatility and functionality.

Corrosion Resistance: Similar to aluminum sheets, Aluminium sheet are naturally resistant to corrosion due to the formation of a protective oxide layer. This property ensures their durability and longevity in outdoor and marine applications, as well as in plumbing and HVAC systems.

Heat Transfer Applications: Aluminum tubes excel in heat transfer applications, such as air conditioning, refrigeration, and heat exchangers. Their excellent thermal conductivity facilitates efficient heat dissipation and energy conservation.

Aesthetic Appeal: Aluminum tubes can also be utilized for decorative purposes. Their sleek and modern appearance, combined with easy customization options, makes them a popular choice for architectural elements like handrails, curtain walls, and furniture.

Conclusion:

The versatility, durability, and exceptional properties of aluminum sheets and aluminum tubes have made them indispensable in numerous industries. From aerospace and automotive to construction and manufacturing, these materials continue to revolutionize various sectors with their unique advantages. The lightweight nature, corrosion resistance, formability, and thermal conductivity of aluminum sheets and tubes make them ideal for a wide range of applications, contributing to innovative designs and sustainable solutions. As technology advances, we can expect aluminum to remain a fundamental material, driving progress and shaping the future across diverse industries.

- SHARES