Introduction:

In the realm of fluid transfer, the choice of hoses plays a pivotal role in ensuring efficiency, safety, and durability. Two essential components in this domain are Fiber Reinforced Suction Hoses and Tank Truck Gravity Drop Fuel Transfer Hoses. In this comprehensive guide, we will delve into the features, applications, and benefits of these critical components for fluid transport in various industries.

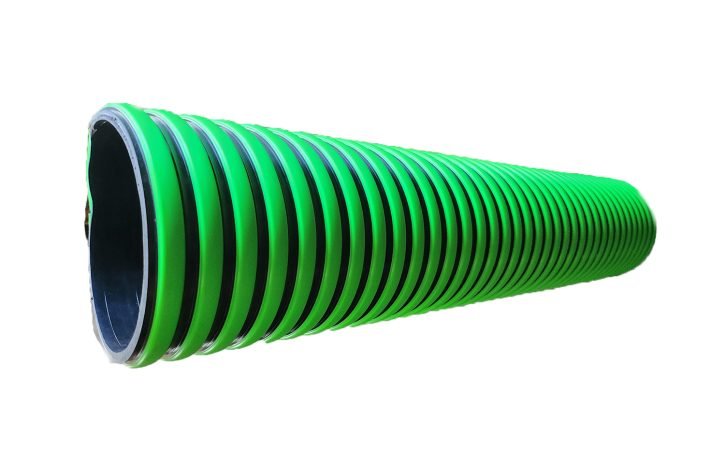

I. Fiber Reinforced Suction Hose:

- Composition and Construction: Fiber Reinforced Suction Hoses are constructed with a blend of materials that typically include a robust inner tube, a reinforcement layer composed of high-quality fibers, and an outer cover for added protection. The combination of these elements creates a hose with excellent flexibility, strength, and resistance to abrasion.

- Key Features:

- Flexibility: The fiber reinforcement in these hoses imparts flexibility, allowing them to bend and adapt to various applications without compromising performance.

- Suction Capabilities: Designed for suction applications, these hoses excel in drawing liquids or materials into the hose, making them ideal for tasks like water, slurry, or chemical transfer.

- Abrasion Resistance: The outer cover protects against abrasion, extending the lifespan of the hose and maintaining its structural integrity.

- Applications:

- Agriculture: Used for irrigation and drainage, these hoses efficiently handle water and other agricultural fluids.

- Construction Sites: Commonly employed for transferring slurries, cement, and other construction-related materials.

- Industrial Processes: Suitable for suction applications in industries such as chemicals, pharmaceuticals, and food processing.

- Benefits:

- Versatility: Fiber Reinforced Suction Hoses are versatile, accommodating a wide range of applications across different industries.

- Durability: The construction with high-quality materials ensures durability, even in demanding environments.

- Ease of Use: With their flexibility and suction capabilities, these hoses are user-friendly and adaptable to various tasks.

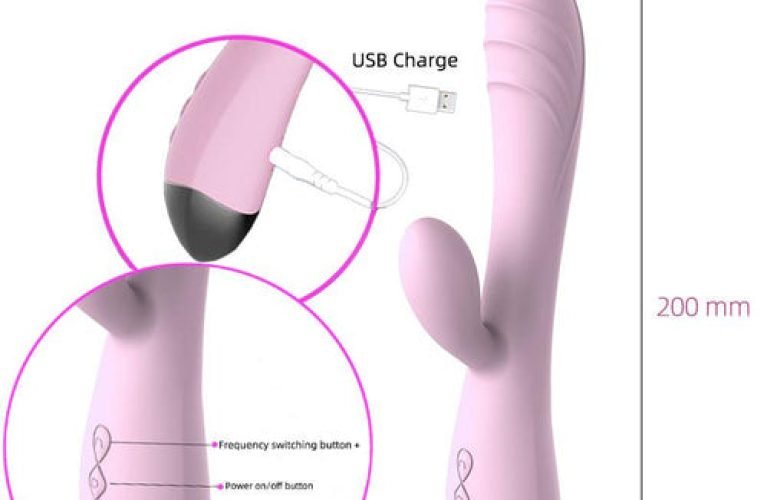

II. Tank Truck Gravity Drop Fuel Transfer Hose:

- Composition and Construction: Tank Truck Gravity Drop Fuel Transfer Hoses are designed specifically for the transfer of fuel and other petroleum-based products. They typically feature an inner tube, reinforcement layers for strength, and an outer cover resistant to abrasion and weathering.

- Key Features:

- Fuel Compatibility: These hoses are engineered to handle a variety of fuels, including gasoline, diesel, and biofuels.

- Static Conductivity: Many tank truck hoses are designed with static-conductive materials to dissipate static electricity, reducing the risk of sparks during fuel transfer.

- Gravity Drop Applications: Suited for gravity drop applications, these hoses facilitate the smooth and controlled transfer of fuel from the tank truck to the receiving storage or dispensing unit.

- Applications:

- Fuel Delivery: Primary use in the transportation and delivery of fuels from tank trucks to storage tanks or dispensers.

- Service Stations: Essential for connecting fuel delivery trucks to underground or aboveground storage tanks at service stations.

- Bulk Fuel Storage: Used in the transfer of bulk quantities of fuel to storage facilities.

- Benefits:

- Safety: Engineered with safety in mind, these hoses are designed to handle flammable liquids with features such as static conductivity to minimize the risk of sparks.

- Performance: Tank Truck Gravity Drop Fuel Transfer Hoses provide efficient and reliable fuel transfer, ensuring that fuel reaches its destination without leaks or spills.

- Durability: Constructed with materials resistant to abrasion, weathering, and the corrosive effects of fuels, these hoses are durable and built for long-term use.

Conclusion:

Both Fiber Reinforced Suction Hoses and Tank Truck Gravity Drop Fuel Transfer Hoses are integral components in fluid transfer applications, each catering to specific needs and industries. Understanding their features, applications, and benefits is crucial for selecting the right hose for a particular task, ensuring the seamless and safe transfer of fluids in diverse industrial settings.

Category

Have any Query? Feel free to drop a mail to us.