Exploring the Wonders of Titanium Pipes and Titanium Tubes

In the realm of modern engineering, the quest for lightweight, durable, and corrosion-resistant materials has led to remarkable advancements. Among these materials, titanium stands out as a true marvel. With its exceptional properties, titanium has found its way into numerous industries, from aerospace and automotive to medical and marine applications. Today, we embark on a journey to understand the wonders of titanium pipe and titanium tubes, exploring their features, applications, and the impact they have on various sectors.

Unveiling the Enigma of Titanium:

Titanium is a chemical element renowned for its impressive strength-to-weight ratio, corrosion resistance, and biocompatibility. It was first discovered in the late 18th century but only came to be utilized for industrial purposes during the mid-20th century. Its widespread application is largely attributed to its unique combination of properties, making it an invaluable resource in several fields.

One of the most remarkable aspects of titanium is its density. It is approximately 45% lighter than steel while still retaining comparable strength. This attribute makes it particularly attractive in industries where weight reduction is crucial, such as aerospace, where it can contribute to increased fuel efficiency and payload capacity.

Titanium Pipes and Tubes:

Among the many forms in which titanium is utilized, pipes and tubes are some of the most significant. These tubular structures are fabricated using titanium alloys to leverage the metal’s exceptional characteristics while tailoring it to specific needs. The processes involved in manufacturing titanium pipes and tubes include extrusion, forging, and seamless tubing techniques.

-

Titanium Pipes:

Titanium pipes are hollow structures with a circular cross-section, designed to transport fluids, gases, or even solids in some cases. The pipes can vary in size and thickness, depending on the application. The corrosion resistance of titanium is of particular importance in chemical processing plants, where it can withstand harsh chemicals, acids, and high-temperature environments without degradation.

Additionally, titanium pipes play a vital role in desalination plants, offering resistance to the corrosive properties of seawater during the desalination process. This makes titanium a preferred material for the construction of heat exchangers and condensers, ensuring a longer operational life for these critical components.

-

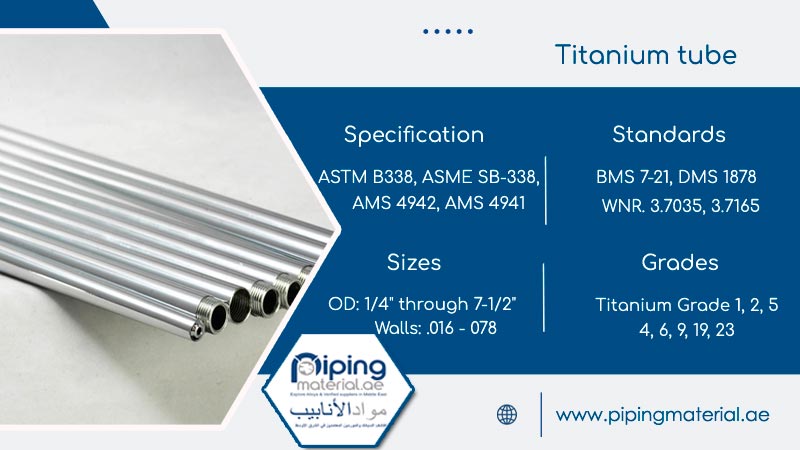

Titanium Tubes:

Titanium tube share many similarities with pipes, but they often have thinner walls and are typically used for structural purposes rather than fluid transportation. In applications like aircraft frames, bicycle frames, and medical implants, the exceptional strength of titanium ensures a robust structure while keeping the overall weight low.

Furthermore, the biocompatibility of titanium makes it a prime choice for medical implants, such as dental implants, joint replacements, and bone plates. Its ability to integrate with living tissue, a phenomenon known as osseointegration, reduces the risk of rejection and promotes faster healing.

The Advantages and Challenges:

The use of titanium pipes and tubes brings about several advantages. These include:

- Corrosion Resistance:Titanium’s immunity to corrosion ensures longevity and reliability in harsh environments, reducing maintenance requirements.

- High Strength:Despite its low weight, titanium possesses remarkable strength, allowing for robust and lightweight structures.

- Biocompatibility:Titanium is biocompatible, making it suitable for medical implants and other healthcare applications.

- Heat Resistance:Titanium can withstand high temperatures, making it suitable for applications in the aerospace and chemical industries.

- Aesthetic Appeal:Titanium’s unique metallic appearance adds to its allure, making it a popular choice in architecture and design.

However, there are also challenges associated with working with titanium. It is a relatively expensive material, and its processing requires specialized equipment and techniques. Additionally, it can be challenging to weld compared to other metals.

The Future of Titanium Pipes and Tubes:

As technology continues to advance, the demand for titanium pipes and tubes is expected to grow. Industries like aerospace, automotive, medical, and marine will continue to benefit from the unique properties of titanium. Researchers and engineers are continually exploring new methods to make titanium more cost-effective and easier to work with, which will further widen its applications.

In conclusion, titanium pipes and tubes represent a testament to human ingenuity and our ability to harness the wonders of nature for our benefit. From the skies to the depths of the ocean, titanium plays a vital role in shaping the world we live in today. As we move into the future, titanium’s versatility and exceptional properties promise to lead us towards even greater technological achievements.